Widest Widths • Strongest Rails • Longer Panels • Maximum Clearances

The Slide Rail system is a vertical sheeting and trench support system. It is used to replace the conventional application of wood or steel sheeting. In using the system, the excavation may be shored from ground level to subgrade without soil movement.

It is a highly effective system in areas having unfavorable ground conditions or where an existing underground infrastructure would pose difficulties in trench support.

By using the modular slide rail system either with side panel lining plates or inline sheeting templates, the system will accommodate a variety of job site requirements.

There is an added benefit to the contractor, in that a significant savings in labor and materials will be realized.

Slide Rail Advantages

- Provides safety while excavating

- Tight sheeting without soil movement

- Vibration free, no damage to adjacent structures

- Saves money: Less material cost than conventional sheeting, finish in a third of the time using half the labor

- Engineered to meet O.S.H.A.

Slide Rail System Videos

SBH Slide Rail - Features & Benefits

11:35 minutes

SBH Trench Shoring Installation

5:24 minutes

SBH Trench Shoring - Strut Free

0:59 minutes SBH Slide Rail Installation

2:31 minutes

Slide Rail Image Gallery - Click to Enlarge

Sample Configurations

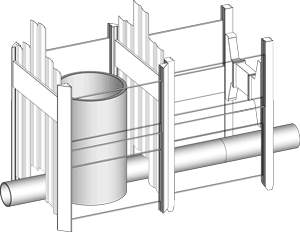

Tight Sheeting System with Rolling Struts

Tight Sheeting System with Rolling Struts

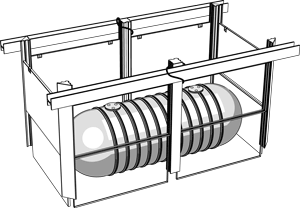

Two Bay Sheeted Pit - Rebraced

Two Bay Sheeted Pit - Rebraced

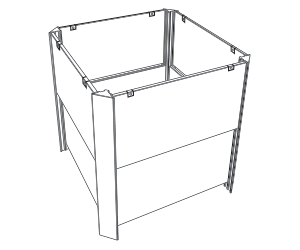

Small Rectangular Pit Closed All Four Sides

Small Rectangular Pit Closed All Four Sides

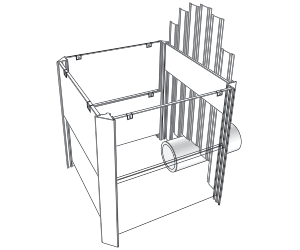

Small Rectangular Pit with Sheeting on One (or Both) Sides

Small Rectangular Pit with Sheeting on One (or Both) Sides

Hydralifter... Less Vibration, Less Noise*

The Hydralifter is a hydraulic panel, post, and steel plate extractor. It is used to break free the inner base and top plates that are used in Slide Rail shoring. The Hydralifter is mounted to an excavator's hydraulic lines and is placed on top of outer panel rigging. The Hydralifter safely and gently removes plates without the use of heavy excavators leading to: safety on the site; less equipment damage; less vibration and noise; saving of time and costs.

*(See Video Above - "SBH Hydralifter")