Optimum Versatility Aluminum Trench Shields

- Steel Framed Aluminum Trench Shields

- AEX Aluminum Framed Trench Shields

- Modular Aluminum Panel Trench Shields/MAPS

- Ultra Shore™ Light Weight Aluminum Trench Shields

- Aluminum Hydraulic Shields & End Shores

- Aluminum End Panels, End Shores & Speed Struts®

Steel Framed Aluminum Trench Shields

Trench Shoring Company and Speed Shore® Aluminum Panel Shields (APS) are now available with a rugged steel frame, creating the only true aluminum-wall “drag box” in the industry. Weighing in at approximately half the weight of comparable steel trench shields. Our steel-framed APS is specifically designed for contractors, utilities, plumbers, and municipalities who prefer the use of a rubber-tired backhoe or light excavator, yet desire a durable, high-capacity, lightweight shield to pull along the trench as work progresses.

The Aluminum-Wall That’s Built to Last

- 2-1/2” aluminum double-wall panels for exceptional strength-to-weight ratios and superior corrosion resistance.

- Exclusive welded steel frame offers the strength and durability that allows this APS to be pulled along the trench as work progresses.

- Foam-filled smooth walls prevent accumulation of water, dirt and debris.

- Thru-wall spreader sockets penetrate end vertical supports for added strength.

- Heavy-duty lifting rings provide for rapid four-point lifting of units.

Steel Framed Aluminum Trench Shields Image Gallery - Click to Enlarge

AEX Aluminum Framed Trench Shields

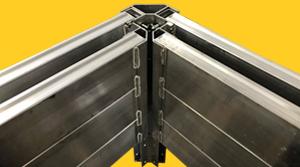

The AEX Trench Shields developed by GME are static walled aluminum trench shields designed from aircraft grade

aluminum. Our AEX Trench Shields are manufactured from extruded aluminum panels to provide protection for a wide range of depths and projects.

Available in 2AEX (2” Thick wall) and 4AEX (4” Thick wall) models, the AEX series are ideal for rubber tired back hoes and small excavators.

Ideal for Today’s Lighter Excavators

- Rugged collar adaptors for 5” x 5” tube steel spreaders

- Lifting eyes

- Optional “no-knife edge” with heavy-duty skid plate

- Standard lengths to 18 feet

- Custom lengths on request

- Certified by a registered professional engineer to meet OSHA standards

AEX Aluminum-Framed Trench Box Image Gallery - Click to Enlarge

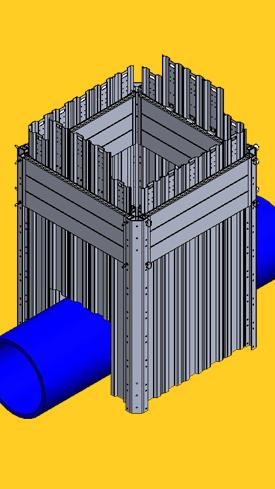

Modular Aluminum Panel Trench Shields/MAPS

Modular Aluminum Panel Shields (MAPS) trench shield system is engineered for high strength, ultra-low weight, and ease of handling. Modular panels, end-members, and adjustable spreaders are light enough for transport by pickup, and can be quickly configured for 2, 3 or 4-sided applications. A two-man crew can readily assemble the

system by hand for rapid placement in the trench by a rubber-tired backhoe.

- Aluminum Alloy Construction for extremely high strength-to-weight ratios and superior corrosion resistance.

- Narrow Double-Wall Panels minimize excavation width while maximizing interior work space.

- Adjustable Spreaders allow for rapid field modification of shield width.

- Lightweight Modular Components afford easy handling and options of 2, 3, or 4-sided shield configurations.

- Dual-Purpose End Members connect both panels and spreaders in multiple configurations.

- Foam-Filled Smooth Walls prevent accumulation of water, dirt and debris.

MAPS Image Gallery - Click to Enlarge

Modular Aluminum Panel Sheeting Guide System

The Modular Aluminum Panel Sheeting Guide is an aluminum sheet pile guide system that fits in place of one of the modular aluminum panels. This allows a line of sheet piles to be placed up to and over obstructions such as cross trench lines. The guide frame may be used at one or multiple wall lines. The sheeting can be installed by hand and may be skipped or overlapped provided there is no sloughing or raveling through the cracks.

![]() Modular Aluminum Panel Sheeting Guide System Literature

Modular Aluminum Panel Sheeting Guide System Literature

Modular Aluminum Panel Sheeting Guide System Image Gallery - Click to Enlarge

Aluminum Hydraulic Shields & End Shores

Speed Shore’s® innovative, patented Shoring Shields* combine the benefits of aluminum hydraulic shoring with the solid-wall security of a static shield. Constructed of high-strength aluminum alloys, Shoring Shields are ideal for municipal maintenance and repair, cable splices, pipeline bellholes, vault placements, trenchless technology pits and light utility installations. The solid-sheeted exterior provides for optimum personnel protection while their lightweight design insures ease of handling with a rubber-tired backhoe.

The Rugged, Lightweight Shoring Solution

- 100% above-ground installation allows complete installation and removal safely from outside the trench.

- High-yield aluminum alloy construction for exceptional strength and lightweight portability.

- Patented hydraulic manifold assures precise control of all cylinders.

- Heavy-gauge sheeting caps and skids for protection of sheeting sidewalls.

- Certification plate on all shields denotes P.E. Certified capacity and operating guidelines.

- Available in either a lightweight corrugated sheeting or the exclusive smooth-wall aluminum panel exterior.

Exclusive Hydraulic Manifold

An exclusive patented hydraulic manifold** allows precise control of each hydraulic cylinder within the Speed Strut from a convenient topside location, which guarantees the safety of the operator until the Shoring Shield has securely shored the trench. The patented protection plate guards the valves and fitting from damage during installation and removal. And the central located supply and bleed valves facilitate rapid installation and removal of the Shoring Shield from the trench, also allowing complete fluid recovery.

*U.S. Patent 5096334 ** U.S. Patent 5209606

Aluminum End Panels

Pre-engineered “end-panels” may be quickly attached to any Shoring Shield for 3 or 4-sided shielding.

End panel brackets simply slide over the end of each wale and are secured by the same quick-connect pins as the Speed Struts®. End panel sizes correspond directly with each Speed Strut size, so that the sheeting guides telescope over the full operating width of the Shoring Shield.

The sheeting guides may be adjusted at the bottom wales to either: (1) prevent the sheeting from passing beyond the bottom wall for pipe clearance, or (2) allow the sheeting to extend to the bottom of the trench for full end closure.

End Shore

Speed Shore’s End Shores come with innovative Speed Struts and are available with optional End Shore Panels. End Shore Panels are also available separately for use with your current inventory of Speed Struts.

Speed Struts®

Shoring Shields feature the exclusive Speed Struts, which incorporate hydraulic cylinders and return springs within rugged telescoping steel sleeves. They allow for 3 and 4-sided trench support, while providing increased protection to critical components. Quick-connect pins and hydraulic fittings permit rapid assembly/disassembly, and changeover to larger or smaller Speed Struts. Speed Struts allow for end-loading capability while providing critical protection for the hydraulic cylinder and spring enclosed within.